| Composition design of Ni–nano-Al2O3–PTFE coatings and their tribological characteristics |

| A Tang, M Wang, W Huang, X Wang, Surface and Coatings Technology, 282, 121-128, (2015) |

| 发布人:戴庆文 发布时间:2020-10-28 浏览次数:245 |

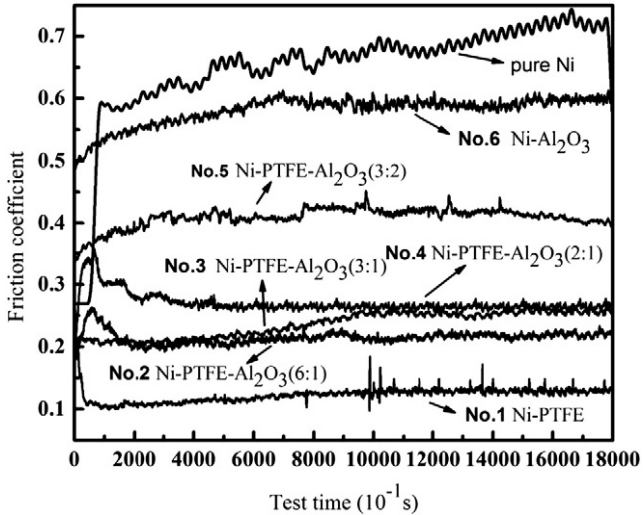

The Ni-nano-Al2O3-PTFE composite coatings were prepared by the electrophoretic-electrochemical deposition method. A uniform film of the nano-Al2O3 and PTFE particles was first electrophoretically co-deposited on the substrate of copper. Then, nickel was electro-deposited on the substrate covering with the film of these particles. Using the electrophoretic-electrochemical deposition method can remarkably increase the particle content in the composite coatings. Under certain conditions, the contents of Al2O3 and PTFE particles in the Ni-nano-Al2O3-PTFE composite coating can reach 26.57 wt.% and 13.79 wt.%, respectively. The results of friction and wear tests showed that the Ni-PTFE composite coating exhibited the lowest friction and the Ni-nano-Al2O3 composite coating possessed the best wear resistance. By optimizing the content ratio of nano-Al2O3 and PTFE particles, the composite coating of Ni-nano-Al2O3-PTFE displays preferable low friction and anti-wear behavior.

全文下载: |