| MoS2/Ti Co-Deposited Coatings and Their Fretting Wear Properties at Elevated Temperatures |

| Shenglin Liang, Qingwen Dai, Wei Huang, Xiaolei Wang (2025) |

| 发布人:戴庆文 发布时间:2024-02-19 浏览次数:704 |

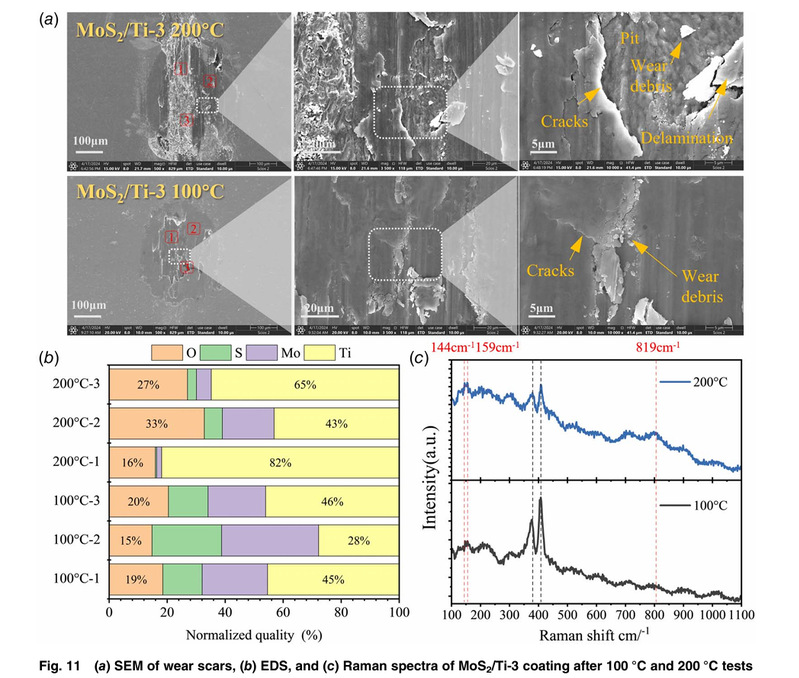

Fretting wear refers to the damage phenomenon experienced by the mechanical compo nents undergoing micro-amplitude relative slip at their contact region due to vibration. Titanium alloys find their extensive application in aerospace industry components such as splines and dovetail joints, where they experience fretting wear phenomenon. This research work investigates the effect of MoS2/Ti co-deposition coatings with varying Ti con tents, deposited on the TC4 titanium alloy substrate using magnetron sputtering. Fretting wear tests were conducted at room temperature, 100 °C, and 200 °C, using a specially designed fretting test fixture with a ball-on-flat contact configuration, mounted on a servo-hydraulic fatigue testing machine. The results indicated that the coating becomes denser with an increase in the Ti content. The coating exhibited the highest hardness and better anti-fretting wear performance at room temperature. However, the effect of Ti content on the fretting wear behaviors changed at elevated temperatures. At the highest Ti content coating, excessive oxide particles were found on the worn surface at elevated temperatures, inducing an abrasive effect and localized cracks. However, coatings with moderate Ti content (9.62 at%) effectively protected the substrate from significant wear at room temperature and maintained a low coefficient of friction at high temperatures without failure. [DOI: 10.1115/1.4067042]

全文下载: |